Safety in Electronics Manufacturing

Business Problem:

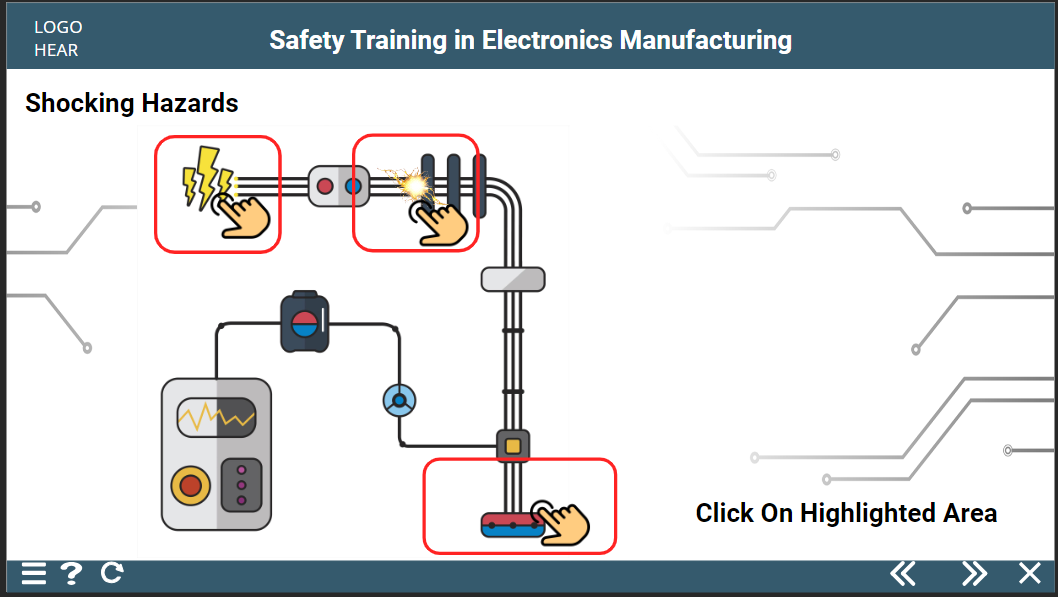

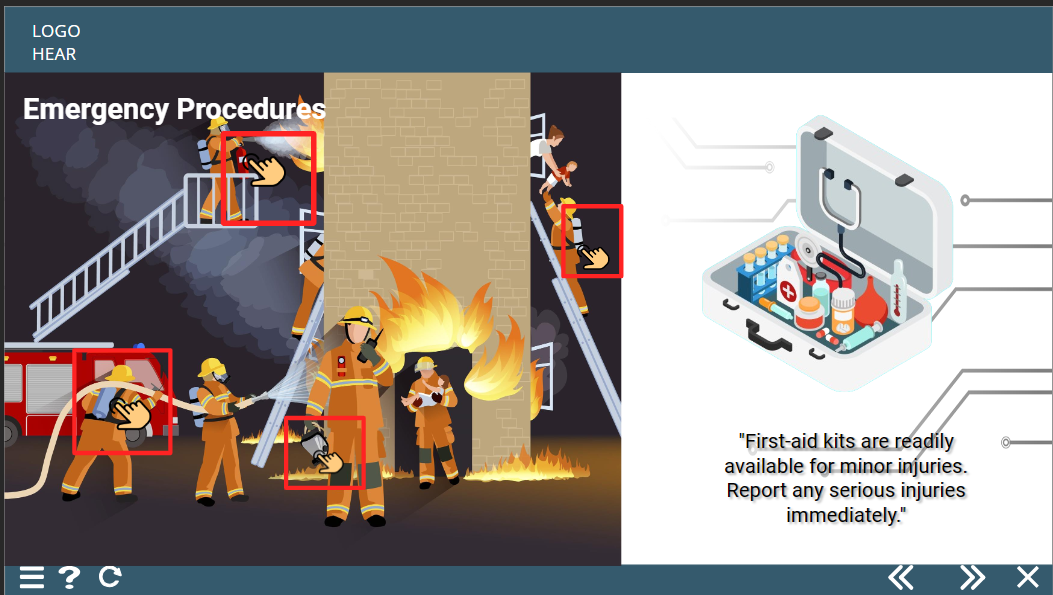

Electronics manufacturing environments present unique safety hazards like exposure to lead, electrical currents, and hazardous materials. Inadequate safety training can lead to worker injuries, illnesses, and even fatalities. Additionally, the fast-paced nature of the industry can lead to shortcuts and non-compliance with safety protocols, increasing the risk of accidents.

ID Approach:

This e-learning program specifically targets electronics manufacturing workers and utilises a blended learning approach, combining online modules with hands-on training to effectively convey safety protocols.

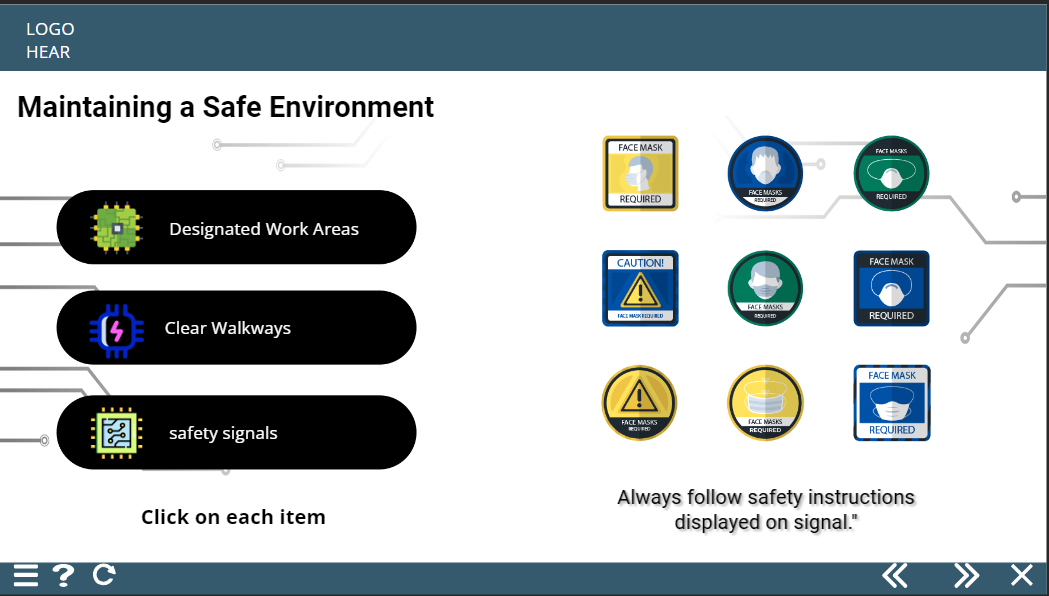

- Interactive Online Modules: Modules with clear explanations, animations, and 360-degree virtual tours of electronics manufacturing facilities to familiarise workers with potential hazards.

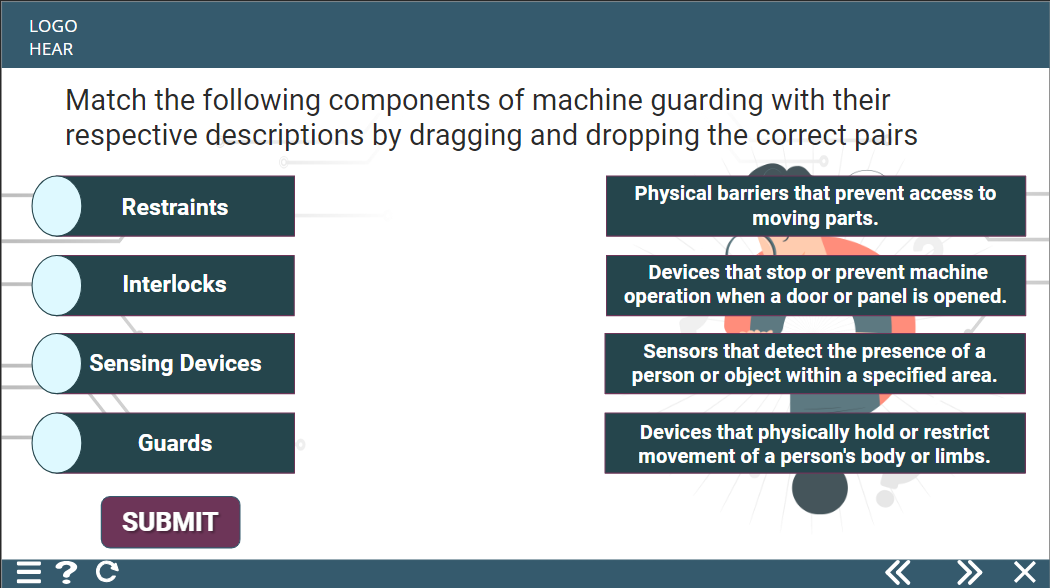

- Scenario-Based Learning: Interactive simulations that place workers in realistic situations where they must identify and address safety concerns specific to electronics manufacturing.

- Equipment-Specific Training: Modules dedicated to the safe operation and maintenance of soldering equipment, chemical handling procedures, and proper Personal Protective Equipment (PPE) use.

Solution:

This e-learning solution empowers electronics manufacturing workers to prioritise safety and work confidently. The program features:

- Job-Specific Focus: Training modules tailored to specific roles and equipment used in electronics manufacturing.

- Interactive Activities: Quizzes, simulations, and gamified scenarios reinforce learnings and encourage safe work practices.